Operations on offshore drilling rigs are inherently weather sensitive. Wind, waves, and currents create vessel motions such as heave, sway, surge, pitch, roll, and yaw, each affecting handling performance and safety.

Even modern floating rigs can experience downtime or increased risk when equipment or systems are not designed for local conditions. The result is often Waiting on Weather (WOW) or increased Non-Productive Time (NPT), both costly and avoidable.

With day rates for high-spec rigs now exceeding USD 500,000 per day (and total daily costs often double that when including support vessels), maximizing uptime is essential. Expanding the operational weather window is a key lever for reducing cost, improving HSE performance, and minimizing emissions.

This article explores modern approaches to controlling lateral movement in the moon-pool area, enabling safer, more efficient, and more sustainable offshore operations.

Why the Moon-pool Area Matters

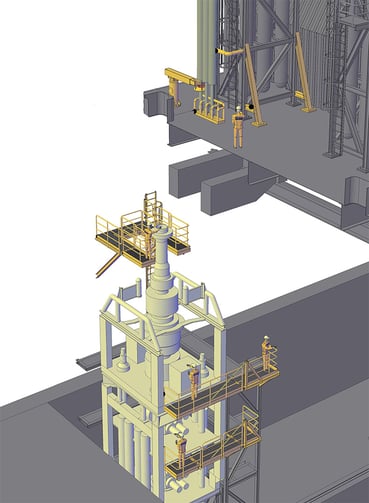

The moon-pool area, located below the drill floor, is one of the most critical zones for motion-sensitive operations. It’s where equipment such as BOPs, XMTs, and risers are handled through the open sea column.

Without effective control of lateral movement, these operations expose personnel and assets to elevated risk, especially in rough weather.

Typical consequences include:

-

Equipment collision or damage

-

Extended downtime (WOW)

-

Increased HSE exposure for deck and subsea crews

Suggested reading: How Tailored Moonpool Handling Systems Can Improve Safety (HSE)

Increasing the operational weather window

The weather window defines the sea-state limits (wave height, wind speed, and current) within which planned rig operations can safely continue. Once conditions exceed those limits, the operation pauses — leading to WOW and NPT.

How to Expand It

-

Reduce lateral offset, sway, and surge: Minimizes relative motion between equipment and structure.

-

Control moon-pool hydrodynamics: Mitigate sloshing and piston effects that amplify movement.

-

Automate critical lifts: Remove personnel from high-risk zones using remote or robotic handling.

-

Retrofit guiding and securing systems: Cost-effective upgrades without major structural modification.

-

Use motion monitoring and analytics: Real-time feedback enables data-driven go/no-go decisions.

Suggested reading: How Can Tailormade XMT Handling Systems Improve your NPT

Solutions for Lateral Movement Control

Various ways to influence the operating weather window exist. The rig design, vessel size, thruster capacity can be designed and constructed at the yard. However, most key parameters related to the rig-design are very expensive to modify after it’s delivered.

Fortunately, there are guiding and fastening technologies available to increase the operational weather window, and its productivity, for an existing vessel. These can be retrofitted to your rig or vessel without altering any of its fundamental architecture.

It can be implemented incrementally, with limited to no interruption to your operation. Furthermore, when considering the cost of downtime and WOW, the return on investment is high.

Preventing Lateral Movement – Safe Material Handling

Arresting lateral movements while equipment is in a parked position or being relocated from one position to another, will enable safe operations in adverse weather and hence increase the operational weather window.

Below the drill floor, where BOPs, Christmas trees (XMTs) and other equipment are moved in and out of the open moon pool, is a good example of an area with numerous, critical material handling processes.

The guiding and fastening technologies that can be applied, are also supported by various degrees of mechanization/automation.

Efficient Guiding Systems – some examples

The moon pool area should be carefully considered when evaluating safe material handling and rig movement in adverse weather conditions. There is a significant potential to optimize safety and operational efficiency by implementing proper guiding systems.

Below is a non-exhaustive list of some of these technologies/products;

-

Riser handling systems

-

Safe and efficient handling of Risers between shuttle and well center

-

-

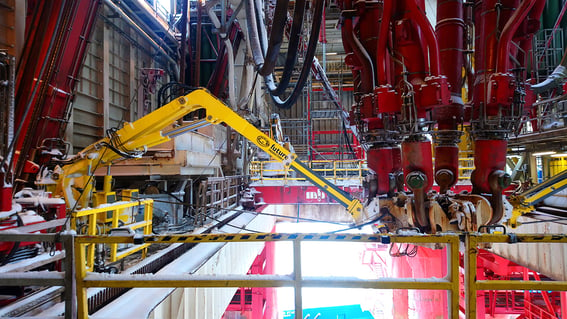

XMT/BOP handling systems with lateral guiding

-

Overhull (OHG) and underhull (UHG) guiding.

-

Remote operated, always secured and handled from storage position to sea (below UHG) and back.

-

See our article How Can Tailored Fitted Xmt Handling Systems Improve Your Npt for illustrations and more information!

-

-

BOP Test pipe handler Systems

-

Remote operated (guided) handling and parking of test pipes

-

Eliminates use of rig crane

-

Increases weather window for BOP testing.

-

The upper and lower arms are telescopic and can raise/lower the pipe into the BOP located below.

-

N-Line / DAT Riser tension handling and parking systems – STR Arms

-

Remote operated handsfree handling and safe parking of riser tension cylinders.

-

Mechanized connection to riser.

-

No manriding operations required.

-

-

Moon pool Multi-purpose cranes

-

Remote operated. Running along rails in the moon pool.

-

Rotation, tilting and telescoping, removes manual work and improves efficiency.

-

Covering large areas of the moon pool.

-

![]()

Additional reading: Redefining MPD Deployment: From 48 Hours to 15 Minutes with FP-ClickStab® Technology

Conclusion

Increasing safety and extending the operational weather window remains a priority in the offshore industry. However, surprisingly many vessels are equipped with inferior systems to arrest lateral movements during critical operations, Even on modern floating drilling rigs. This results in unnecessary WOW and subsequent loss of/reduced day rate.

Arresting lateral movements should be a focus area to secure equipment in parked position and while being moved between locations. Technology, with varying degree of mechanization and automation, is available to resolve these issues and will increase safety, efficiency, and your operational weather window.

Based on the day rates for drilling rigs being in the USD 500.00 region and that the cost for supporting vessels/services are two times that, the return on investment on such technology can be significant.

Increasing the operational weather window will also reduce the time required to complete the drilling operations on location, meaning less emissions to the environment.

Key takeaways

-

The moon-pool is a critical bottleneck for weather-limited operations.

-

Lateral-movement control directly impacts uptime, HSE, and emissions.

-

Retrofittable guiding and automation solutions provide high ROI.

-

Integration of heave compensation and digital motion control extends operational limits.

-

Investing in moon-pool handling technology enhances safety and contract competitiveness.

SUBMIT YOUR COMMENT